Wuyang Textile Machinery has been working hard in the warp knitting industry for more than 30 years, never forgetting its original intention. It has always been Wuyang Textile Machinery's efforts to provide customers with value and create opportunities for the industry. A few days ago, Wuyang Textile Machinery and Sirius reached a consensus that the contract amount signed by both parties exceeded 13 million yuan.

Changshu Sirius Knitting Machinery Co., Ltd. became attached to Wuyang eight years ago, and chose the equipment of Wuyang Textile Machinery Co., Ltd. just after entering the industry without knowing anything. In the case of zero production and customer base, I entered the warp knitting industry, and learned little by little, even took many detours. From 2013 to 2020, from Guangzhou market to Nantong market, from processing to receiving orders, we have finally become more and more stable and soaring in the warp knitting industry! Cerris began to replace 2292 equipment at the end of 2018, specializing in making short hair and strictly controlling the quality. In recent two years, as the volume of the plush market has increased year by year, this year's demand is soaring! Because the existing workshop area is not enough, this year Serus decided to expand the production scale. The total area of the new workshop is 12582 square meters, which directly expanded the production capacity by more than three times!

Ms. Zhang Mei, the boss of Cerus, said, "I have accumulated a lot of experience and good customers in the past eight years. Their support group has given me great support, so my positioning is to go high-end!"

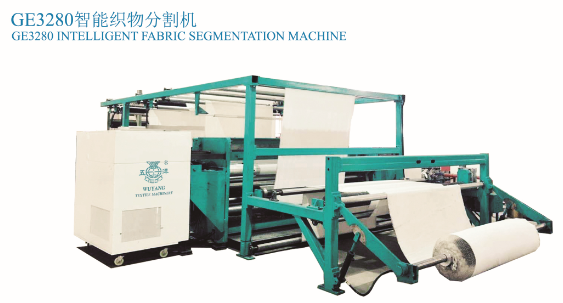

The equipment that Cerris purchased from Wuyang Textile Machinery includes more than 50 different types of warp knitting machines and an intelligent fabric divider. All three types of warp knitting machines adopt stable and reliable bus control system, including electronic let off and electronic traverse. Among them, GE2292 high-speed double needle bed warp knitting machine is mainly used for weaving short velvet products; GE2885/GE2886 double needle bed warp knitting machine is mainly used to weave jacquard velvet fabrics to meet the market demand for a wide range of products. At the same time, Wuyang Textile provides customers with free process development and design services and protects their copyright. GE3280 intelligent fabric divider mainly solves the industry pain point, greatly improves the cloth surface quality after cutting, and can ensure that the whole AB surface error is within 1% (the measured AB surface error of 600KG cloth roll is less than 0.5KG).

After upgrading the equipment, Cyrus will better control the efficiency and quality of finished products on the original basis, and improve the market competitiveness. Combined with the new live broadcast sales model in recent two years, Seize the opportunity, and Sirius will become a dark horse in the market. Wuyang Textile Machinery will also give full support to achieve a win-win situation with customers!

中文

中文 English

English Spanish

Spanish TurkishTurkish

TurkishTurkish Arabic

Arabic Vietnamese

Vietnamese